I have a SRAM GXP crankset (pictured below)

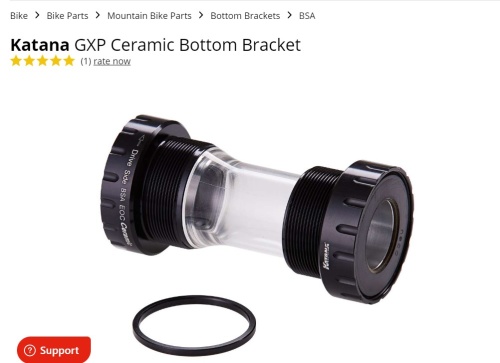

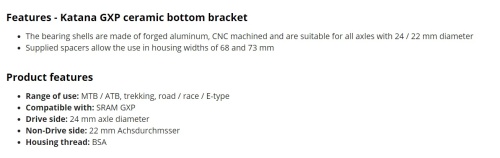

I bought this BB for it. A Katana GXP Ceramic BB

https://www.bike-discount.de/en/katana- ... om-bracket

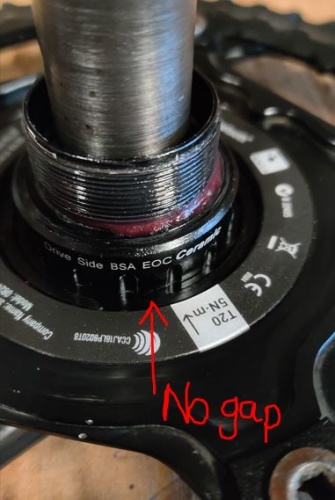

Problem is when I install the crankset - the NDS arm compresses in against the bearing cover and then the cranks don't really rotate. Much too much load on the bearings. See pic below

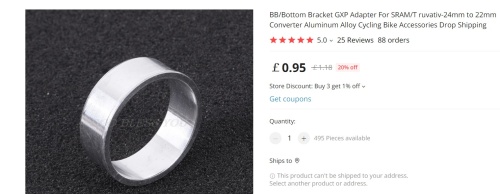

I came across these small little adapters that basically sit between the bearing and the spindle, buy surely fitting one of these will mean the spindle can't fit through? I think these are to convert Shimano BB to GXP????

So what to I need to install these cranks correctly? Thanks