preview: Al33 kickstarter launch (new 33mm deep toroidal shaped aluminum rims (465gram) + wheels)

Moderator: robbosmans

Visit starbike.com Online Retailer for HighEnd cycling components

Great Prices ✓ Broad Selection ✓ Worldwide Delivery ✓

www.starbike.com

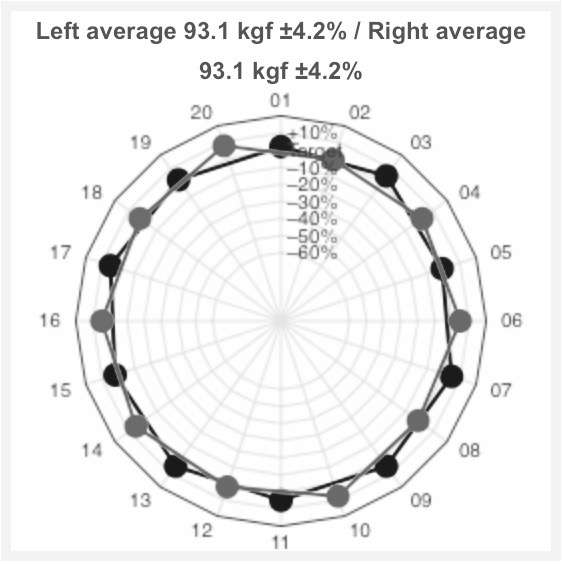

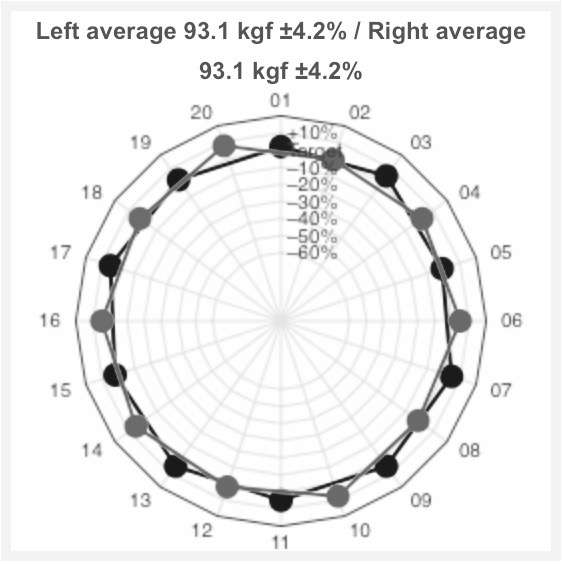

i recommend @bellebikes that you spend some of your kick starter $$ on a more professional tension meter if you want to actually build wheels at sub 5% tension deviation. The TM-1 is a hobby/basic workshop tool.. Its ok for getting the tension ball park on a set of wheel if its calibrated pretty much every session. But asking it to read 5% or less deviation across a wheel is outside of its capacity. It's readings are affected by how you release onto the spoke.. The repeatability is a major flaw, and if you know this its not hard to fudge the numbers. Parks rate it to 10% best case but from experience I'd say its more like 15%.. At the tension levels you are using i'd recommend the high end unit that your spoke MFG endorses as they tend to have really good calibration charts for their own spokes.. e.g. the Dt swiss or Sapim meters

-

bellebikes

- in the industry

- Posts: 30

- Joined: Tue Apr 05, 2016 1:40 pm

- Location: Warmond

- Contact:

sugarkane wrote:i recommend @bellebikes that you spend some of your kick starter $$ on a more professional tension meter if you want to actually build wheels at sub 5% tension deviation. The TM-1 is a hobby/basic workshop tool.. Its ok for getting the tension ball park on a set of wheel if its calibrated pretty much every session. But asking it to read 5% or less deviation across a wheel is outside of its capacity. It's readings are affected by how you release onto the spoke.. The repeatability is a major flaw, and if you know this its not hard to fudge the numbers. Parks rate it to 10% best case but from experience I'd say its more like 15%.. At the tension levels you are using i'd recommend the high end unit that your spoke MFG endorses as they tend to have really good calibration charts for their own spokes.. e.g. the Dt swiss or Sapim meters

Already have a measurement device from spoke MFG, with very accurate readings.

However we have different wheel-builders, And one builder took this one home over the weekend when finishing some wheels. So in the video we use park tool.

But they are checked and, if necessary, adjusted to the 5% accuracy promised.

We will buy one or two extra high quality meters if we reach our kickstarter goal tough,

Well noted BTW

matty wrote:Shame looks like I missed out on the wheels. Only 2 gone when I was thinking about it and waiting on hub dimensions and now all gone at that price point.

I was too late with dimensions, forgot about it, consider it my fault, Therefore send me a PM on kickstarter and we will sort it out.

EDIT: DIMENSIONS:

Flange offset (From center)

DS: 16mm +2 = 18mm (68mm flange diameter) (really as wide as you can get without coming dangerously close to the spokes)

NDS: 37mm +2 = 39mm (42mm flange diameter)

Front Wheel: 35mm +2 = 37mm (34mm flange diameter)

*+2 for effective offset (because of ET2 drilling)

http://www.bellebikes.com - info@bellebikes.com

Rides: Bellezza Stelvio <5kg and Bellezza CorsaX!

Rides: Bellezza Stelvio <5kg and Bellezza CorsaX!

bellebikes wrote:EDIT: DIMENSIONS:

Flange offset (From center)

DS: 16mm +2 = 18mm (68mm flange diameter) (really as wide as you can get without coming dangerously close to the spokes)

NDS: 37mm +2 = 39mm (42mm flange diameter)

Front Wheel: 35mm +2 = 37mm (34mm flange diameter)

*+2 for effective offset (because of ET2 drilling)

Using an offset rim doesn't mean that the flange spacing you quote is as wide as you can get. If you combined an offset rim with a DS flange spacing of 18mm it would improve strength/stiffness even further. A flange spacing of 18mm and an offset rim isn't mutually exclusive.

FWIW, I have wheels built with standard rims to 18mm flange spacing, offset rims to 18mm spacing (using Alchemy rear hubs) and even have a preproduction model of another hub with 19.3mm that's laced to a 65mm rim. None of these combinations interfere with the rear mech. That hub design could be easily improved with better flange spacing.

J-Bend spokes are not a weak spot with wheels. There are hundreds of thousands of wheels out there with J-bend spokes. When built correctly and stress relieved, the spokes will outlast the rims. I find that most companies prefer straight pull hubs because it reduces building time.

Are these rims the same as the Flo 30?

-

bellebikes

- in the industry

- Posts: 30

- Joined: Tue Apr 05, 2016 1:40 pm

- Location: Warmond

- Contact:

Here some input why we made some decisions.

I do agree that we take a little safety margin, you have to imagine that part of our customers has bended derailleur pads and don't even notice, Also we work with a lot of racers, And they do crash a lot and have to finish their race's with bended derailleur pads, Maybe we could consider moving to 17mm, but instead of moving very close to the derailleur we chose for a 2mm offset at the hub. with 16 spokes at the drive side with an effective 18mm flange offset proves to be plenty stiff. Also a bigger flange diameter gives less room for offset.

Our hubs are not 131mm but 130mm, We opted for 130mm because we work with a lot of racers, and a real fast wheel change is important for them, Making the hub 1mm wider won't be a problem for recreational rider, But we found that rear wheel replacement wasn't as fast as with 130mm wide hubs. because you will have to pull the rear fork a little outward. But this limits the offset by another .5mm. Tomorrow i will post a picture of the derailleur hanger clearance to spoke's. There is less than 2mm room i can assure you.

Again, due to the criss-cross drilling spoke holes 2mm offset we effectively create 18mm offset, with 16 spokes at the drive side and 66mm flange diameter. These values combined offer a really stiff lateral wheel.

We had internal testing of both Straight-pull and J-bend spokes, in all cases the straight pull spokes lasted longer. We know modern j-bend spokes are reliable, I know most wheels have j-bend spokes, but for us that was not an argument, even if the reliability would have the smallest improvement we thought it was worth it. Also our real test results show that we now and then get a wheel back with a broken nipple at the j-bend (they were stress relieved, not often, i admit that and also most failures happened after getting into contact with another bike. But we so far had 0 failures at this point with straight pull spokes and we quite like it that way,

The combination of internal nipples, thicker spokes at the non-drive-side and straight pull spokes makes that even at accidents the spokes will bend and damage but not break. and because there are only 8 spokes at the NDS, 1 spoke failure makes the wheel unusable.

It does reduce lacing time a little bit, But we are talking about a few minutes, but due to a more complicated shape it does improve manufacturer's costs.

Short answer, No.

This rim is developed from scratch by our company.

They both feature a toroidal shape.

But if you look at the specs the weight difference is about 100 grams, The alloy used is different, Our rim is 32,5mm deep and 26,2mm deep. Flo is 30mm deep and 25.96mm wide according to our website.

But we know that external nipple's are prefered by a lot of wheel-builders, The same for J-bend spokes. We are absolutely not saying anything is wrong with that. But we have a different vision on this. But if customers or bike shops prefer external nipples, no problem and nothing wrong with it. we offer our rim also with external nipples.

ergott wrote:Using an offset rim doesn't mean that the flange spacing you quote is as wide as you can get. If you combined an offset rim with a DS flange spacing of 18mm it would improve strength/stiffness even further. A flange spacing of 18mm and an offset rim isn't mutually exclusive.

I do agree that we take a little safety margin, you have to imagine that part of our customers has bended derailleur pads and don't even notice, Also we work with a lot of racers, And they do crash a lot and have to finish their race's with bended derailleur pads, Maybe we could consider moving to 17mm, but instead of moving very close to the derailleur we chose for a 2mm offset at the hub. with 16 spokes at the drive side with an effective 18mm flange offset proves to be plenty stiff. Also a bigger flange diameter gives less room for offset.

fairwheelbikes on hub review: wrote:So as you can see, the trick here is to find the best compromise. Now that nearly every hub offered is 11 spd compatible, we’ve seen some convergence of hub geometry. Most manufacturers are now “cheating” a little by making the axle 131mm long rather than 130mm long. I think Alchemy was the first to do this several years ago. This 1mm increase gives you an extra 0.5mm of DS offset capability. The maximum possible DS offset is now 18mm and most hubs are around 17mm.

Our hubs are not 131mm but 130mm, We opted for 130mm because we work with a lot of racers, and a real fast wheel change is important for them, Making the hub 1mm wider won't be a problem for recreational rider, But we found that rear wheel replacement wasn't as fast as with 130mm wide hubs. because you will have to pull the rear fork a little outward. But this limits the offset by another .5mm. Tomorrow i will post a picture of the derailleur hanger clearance to spoke's. There is less than 2mm room i can assure you.

ergott wrote:FWIW, I have wheels built with standard rims to 18mm flange spacing, offset rims to 18mm spacing (using Alchemy rear hubs) and even have a preproduction model of another hub with 19.3mm that's laced to a 65mm rim. None of these combinations interfere with the rear mech. That hub design could be easily improved with better flange spacing.

Again, due to the criss-cross drilling spoke holes 2mm offset we effectively create 18mm offset, with 16 spokes at the drive side and 66mm flange diameter. These values combined offer a really stiff lateral wheel.

ergott wrote:J-Bend spokes are not a weak spot with wheels. There are hundreds of thousands of wheels out there with J-bend spokes. When built correctly and stress relieved, the spokes will outlast the rims. I find that most companies prefer straight pull hubs because it reduces building time.

We had internal testing of both Straight-pull and J-bend spokes, in all cases the straight pull spokes lasted longer. We know modern j-bend spokes are reliable, I know most wheels have j-bend spokes, but for us that was not an argument, even if the reliability would have the smallest improvement we thought it was worth it. Also our real test results show that we now and then get a wheel back with a broken nipple at the j-bend (they were stress relieved, not often, i admit that and also most failures happened after getting into contact with another bike. But we so far had 0 failures at this point with straight pull spokes and we quite like it that way,

The combination of internal nipples, thicker spokes at the non-drive-side and straight pull spokes makes that even at accidents the spokes will bend and damage but not break. and because there are only 8 spokes at the NDS, 1 spoke failure makes the wheel unusable.

It does reduce lacing time a little bit, But we are talking about a few minutes, but due to a more complicated shape it does improve manufacturer's costs.

ergott wrote:Are these rims the same as the Flo 30?

Short answer, No.

This rim is developed from scratch by our company.

They both feature a toroidal shape.

But if you look at the specs the weight difference is about 100 grams, The alloy used is different, Our rim is 32,5mm deep and 26,2mm deep. Flo is 30mm deep and 25.96mm wide according to our website.

But we know that external nipple's are prefered by a lot of wheel-builders, The same for J-bend spokes. We are absolutely not saying anything is wrong with that. But we have a different vision on this. But if customers or bike shops prefer external nipples, no problem and nothing wrong with it. we offer our rim also with external nipples.

http://www.bellebikes.com - info@bellebikes.com

Rides: Bellezza Stelvio <5kg and Bellezza CorsaX!

Rides: Bellezza Stelvio <5kg and Bellezza CorsaX!

sugarkane wrote:i recommend @bellebikes that you spend some of your kick starter $$ on a more professional tension meter if you want to actually build wheels at sub 5% tension deviation. The TM-1 is a hobby/basic workshop tool.. Its ok for getting the tension ball park on a set of wheel if its calibrated pretty much every session. But asking it to read 5% or less deviation across a wheel is outside of its capacity. It's readings are affected by how you release onto the spoke.. The repeatability is a major flaw, and if you know this its not hard to fudge the numbers. Parks rate it to 10% best case but from experience I'd say its more like 15%.. At the tension levels you are using i'd recommend the high end unit that your spoke MFG endorses as they tend to have really good calibration charts for their own spokes.. e.g. the Dt swiss or Sapim meters

I just built a tension meter calibrator last week and tested my Park. It was within 1% accuracy and repeatability. I tested a 2mm straight and 1.5mm double butted at around 100kgf (whichever value on the chart was closer). Total cost of my calibrator was $40. To say I was pleasantly surprised is an understatement....

That's a pretty good result did you use a set of scales?

-

bm0p700f

- in the industry

- Posts: 5777

- Joined: Sat May 12, 2012 7:25 pm

- Location: Glermsford, Suffolk U.K

- Contact:

I hope your rims are what you claim. I would be interested a getting a pair but the weight is hard to believe. Are you making the rims in house? Whild i see the point in triplet lacing it does not lead to a stiffer wheels. Offset drilled rims combined with a stiff rim seem to be enough with a 24 spoke rear wheel to create a very reliable wheel. I get what you are doing though.

The one issue i see is how are you going to control the roundness of the rims. I always shoot for eveb tension each side and no matter the brand of rim, pacenti, hed, dt swiss, h plus son, kinlin, ryde the wheel is rarely rojnd to 0.2mm 0.5 or 0.6mm is normal 0.7mm happens much beyond that ig is a duff rim. The thing is even hed rims are not round to 0.1mm and it is practically impossible to radially true many rims now to that level. With some rims it is not worth trying as the tension changes needed are too large.

So if hed rims are round to 0.5mm ( o.k i am taking the last few pairs as an example mostly they can bd better) with even tension i wonder how you are going to acheive better.

Also shooting for such a tight radial target is quite pointless as it probably means alot of rim wastage even though 0.5mm is not noticeable when you ride.

I hope you pull this off but given no one else has, if you do it will be impressive.

The one issue i see is how are you going to control the roundness of the rims. I always shoot for eveb tension each side and no matter the brand of rim, pacenti, hed, dt swiss, h plus son, kinlin, ryde the wheel is rarely rojnd to 0.2mm 0.5 or 0.6mm is normal 0.7mm happens much beyond that ig is a duff rim. The thing is even hed rims are not round to 0.1mm and it is practically impossible to radially true many rims now to that level. With some rims it is not worth trying as the tension changes needed are too large.

So if hed rims are round to 0.5mm ( o.k i am taking the last few pairs as an example mostly they can bd better) with even tension i wonder how you are going to acheive better.

Also shooting for such a tight radial target is quite pointless as it probably means alot of rim wastage even though 0.5mm is not noticeable when you ride.

I hope you pull this off but given no one else has, if you do it will be impressive.

i agree

0.2-0.5mm is what you get from HED belgiums and they are easily the best alloys on the market right now. i build a lot of them and they have gone from good to out standing over the last 6 months.. very round and very true. often very close from the beginning of the build.

IMO chasing good tension is way more important than absolute radial true..

0.2-0.5mm is what you get from HED belgiums and they are easily the best alloys on the market right now. i build a lot of them and they have gone from good to out standing over the last 6 months.. very round and very true. often very close from the beginning of the build.

IMO chasing good tension is way more important than absolute radial true..

-

nobrainer32

- Posts: 6

- Joined: Mon Jul 25, 2016 10:29 pm

- Location: Berlin / Germany

Very interesting campagne. How would you rate the rim compared to a similar carbon rim. What are the benefits / disadvantages?

Gesendet von iPhone mit Tapatalk

Gesendet von iPhone mit Tapatalk

-

bellebikes

- in the industry

- Posts: 30

- Joined: Tue Apr 05, 2016 1:40 pm

- Location: Warmond

- Contact:

nobrainer32 wrote:Very interesting campagne. How would you rate the rim compared to a similar carbon rim. What are the benefits / disadvantages?

First of all, not all carbon rims are the same, and i am not going to claim i tested them all.

but we designed our wheels to behave as much like carbon wheels.

Obvious disadvantage from carbon rims are their price. they are more costly to produce.

Also in wet the braking power is different from just plain terrible to acceptable (in general the more expensive brands do achieve acceptable braking performance , they provide their brake surface's with a coating like basalt)

Also heat buildup in carbon rims tend to be a problem on downhill sections for heavier riders. but a good carbon rim uses a resign which won't melt up to 200-250 degree, also some other tricks can be used + optimized brake pads.

For tubes and deeper clinchers there is a weight advantage, The toroidal shape can be lighter with carbon, however the clincher bed is heavier in general,

With using a very hard aluminum and lots of optimization we achieved a weight comparable to mid-height carbon rims, But if you go deeper there will be a weight advantage for carbon.

Looks for a carbon rim are in general more appreciated, especially because of their black brake track and carbon looks good.

We tried to achieve good looks by using a sandblasted finish and using a ceramic coating on the brake surface.

We would rate the performance and durability of our ceramic surface very good, but fact remains that it is a coating, it is subject to wear and over time it will wear lighter. But if you keep your brake-pads clean and your brake surface they really last long. much longer compared to anodized coatings. Also it extends rim life as when your braking on the coating the aluminum won't wear.

But rim brake wheels are subject to wear, the forever lasting black coating on aluminum rims does not exist. Carbon is also subject to wear but the color of carbon is black so it will stay perfectly black.

bm0p700f wrote:I hope your rims are what you claim. I would be interested a getting a pair but the weight is hard to believe. Are you making the rims in house?

Please see the alloy spec chart i posted earlier. Harder alloy is harder and therefore more expensive to work with, but i think it is absolutely worth it.

Also this is a quote from a US distributor after he built a set of wheels with our rims:

Jan,

The front hub built up nicely. Might not have the rear done until wednesday - wheel builder is swamped... ...but he did notice the hardness of the alloy - well done.

2 days later:

The builder rode the front wheel yesterday and is very impressed.

Wheel building is inhouse, rims are not made in house, they are made in taiwan.

bm0p700f wrote:Whild i see the point in triplet lacing it does not lead to a stiffer wheels. Offset drilled rims combined with a stiff rim seem to be enough with a 24 spoke rear wheel to create a very reliable wheel. I get what you are doing though.

The lacing pattern itself does not, i agree, stiffness is won at the driveside (because of using 16 spokes instead of 12) and stiffness is lost at NDS, but we compensate that with using stiffer/heavier spokes

bm0p700f wrote:The one issue i see is how are you going to control the roundness of the rims. I always shoot for eveb tension each side and no matter the brand of rim, pacenti, hed, dt swiss, h plus son, kinlin, ryde the wheel is rarely rojnd to 0.2mm 0.5 or 0.6mm is normal 0.7mm happens much beyond that ig is a duff rim. The thing is even hed rims are not round to 0.1mm and it is practically impossible to radially true many rims now to that level. With some rims it is not worth trying as the tension changes needed are too large.

To be clear we built to +/-0.1mm round so you could say 0.2mm total, but if you include the welded part (5cm from the weld) you will measure a little higher.

bm0p700f wrote: Also shooting for such a tight radial target is quite pointless as it probably means alot of rim wastage even though 0.5mm is not noticeable when you ride.

I hope you pull this off but given no one else has, if you do it will be impressive.

Good point there, If you look at a roundness of a tire, you could ask yourself what makes sense. However when it comes to a marketing standpoint it has its benefits.

sugarkane wrote:i agree

i agree

0.2-0.5mm is what you get from HED belgiums...

As said, when it comes to roundness i would say we compare to the best alloy rims on the market.

ihs0yz wrote:This looks good! Very good price point too. I'm honestly not too keen on buying a product without some real world feedback though so I'm going to wait this one out. Will you keep selling this as a part of your permanent product line?

We are working on getting independent reviews. hope to update you on this soon.

We did do real life testing with test riders tough, and i am a racer myself (except for the last 2 months because of a crash during a team time trial training).

Yes, but cant say anything about release date for getting the rims stocked without a waiting list. Asap, but kickstarter backers are in front of the line.

http://www.bellebikes.com - info@bellebikes.com

Rides: Bellezza Stelvio <5kg and Bellezza CorsaX!

Rides: Bellezza Stelvio <5kg and Bellezza CorsaX!

Visit starbike.com Online Retailer for HighEnd cycling components

Great Prices ✓ Broad Selection ✓ Worldwide Delivery ✓

www.starbike.com

Could you give me the contact information of the US distributor?

Thanks

Thanks